We all have a role to play to protect our drinking water

If you own a business, own a multi-dwelling such as a unit, or use an alternate water supply, you may be required to have a backflow prevention device installed on your property.

If you already have, you may be required to have it tested every year to ensure it’s working properly.

It’s important because backflow – which can occur when there’s a sudden differential in water pressure – can result in contaminated water reversing out of a property’s water system and back into our drinking water supply.

Our audit teams are constantly conducting random checks to ensure the compliance that’s so vital to our ability to provide clean, safe drinking water.

What is backflow?

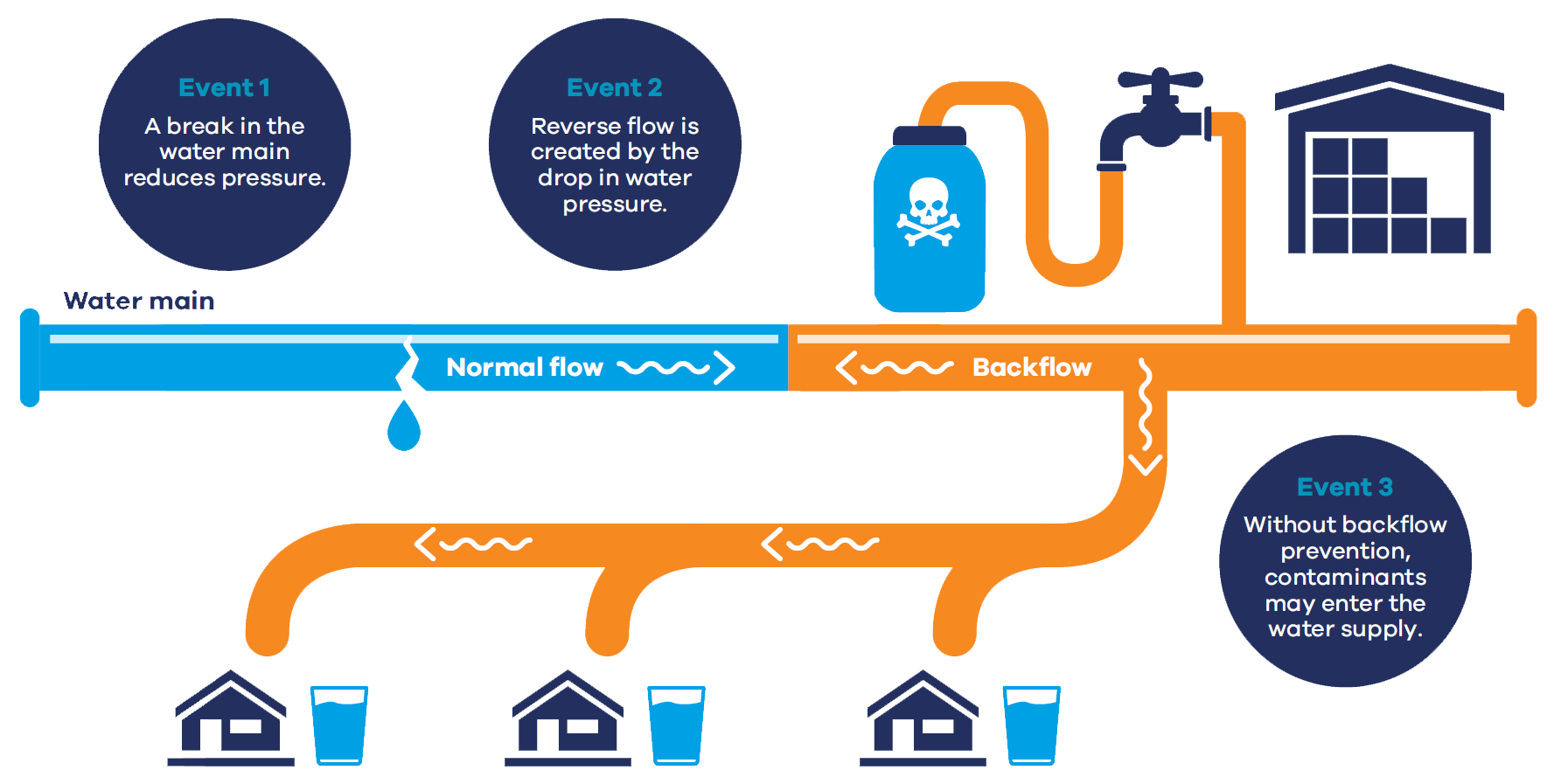

Backflow is the unwanted reverse flow of water from a property back into the water supply. In simple terms, used water that may be contaminated goes back into our drinking water and could end up in someone’s glass.

This can occur when there is a sudden differential in water pressure, such as when there is a break in a water main, when a large volume of water is pumped from the main during a fire, or when a property has a higher pressure than the water supply system.

These backflow events cause water that may be contaminated from common business or residential activities to be drawn back into the water supply.

For example, consider a business owner cleaning a grease trap with a hose. Without the appropriate protection in place, a backflow event could cause the contaminated water from the grease trap to go back up the hose and mix into the water supply.

A severe backflow incident can cause contaminants to enter our drinking water and may endanger a person’s health, or in extreme cases, a person’s life.

Do backflow events actually occur?

Yes, unfortunately they do. Backflow events have occurred in the Territory as recently as 2019.

That’s why it’s so important that we all play our part.

How we can prevent backflow

The best way to prevent backflow is for potentially ‘at-risk’ properties to install and maintain a suitable device.

To determine whether your business or multi-dwelling is ‘at-risk’, you’ll need a backflow accredited plumber to assess your hazard level.

‘Medium’ and ‘high’ risk properties must have a backflow prevention device installed. Importantly, these devices must be tested every year to ensure they work.

If your property is deemed ‘low’ risk, you may still require a device.

What do I need to do?

If you are a business owner, it is important that you engage a backflow accredited plumber as soon as possible to determine your property’s hazard level.

Similarly, if you own a multi-dwelling such as a unit, or you rely on an alternate water supply such as a bore or water re-use system, you will need to engage a plumber to determine your next steps.

A backflow accredited plumber will determine your hazard level, install a backflow prevention device if you need one, or complete the required annual testing if you already have one. Your plumber will then forward the details to Power and Water. We’ll keep a register of your device and advise in writing when it’s time for your next annual test.

Our audit teams are constantly conducting random checks to ensure the compliance that’s so vital to our ability to provide clean, safe drinking water.

For more information see our Backflow Prevention brochure PDF, 417.4 KB .

Approved backflow prevention devices

If your property requires a backflow prevention device, there are a number of approved devices available. These include:

- A break tank with a registered air gap

- Reduced Pressure Zone device (RPZD)

- Double Check Valve (DCV)

- Dual Check Valve (DuCV)

- Single Check Valve Springs Loaded – Fire Services only (SCVT)

A backflow accredited plumber or qualified water industry representative will be able to determine which device is best suited to your property.

Examples of typical hazard levels

The following list is to be used as a guide only. Only a backflow accredited plumber or water industry representative can determine your property’s hazard level.

High-risk installation

- car and factory washing facilities

- chemical plants, factories, or dispensing facilities

- commercial laundries

- hospitals, mortuaries, autopsy facilities, clinics

- funeral parlours

- premises with boiler, chiller, or cooling tower makeup water system

- premises with an alternative water supply

- veterinary clinics and similar facilities

- dump point, black water points.

Medium-risk installation

- caravan parks

- commercial swimming pools, spas, and fountains

- food and beverage processing plants

- irrigation systems on non-domestic properties

- secondary school laboratories.

Low-risk installation

- hair salons or troughs

- in-line water softeners and water filtration equipment

- irrigation systems on domestic properties

- private bores of known water quality on residential properties

- rainwater tanks on residential properties.

Manuals and forms for certifiers (trade use)

Backflow prevention manual

This Manual applies to all Power and Water Corporation potable water supply systems licensed under the Water Supply and Sewerage Services Act . Effective: 1 July 2009.

Backflow prevention manual (July 2009) PDF, 203.95 KBAir gap and registered break tank test certification report

Should be completed by the certified licenced plumber and emailed to backflowprevention.pwc@powerwater.com.au.

Air gap and registered break tank certification report PDF, 86.09 KBNotice of installation of backflow prevention device

Should be completed by the certified licenced plumber and emailed to backflowprevention.pwc@powerwater.com.au when they have installed a backflow prevention device at a property.

Notice of installation of backflow prevention device PDF, 94.12 KBRemoval of backflow prevention device application

Should be completed by the certified licenced plumber and emailed to backflowprevention.pwc@powerwater.com.au.

Removal of backflow prevention device application PDF, 90.96 KBValve test certification report for backflow prevention device

Should be completed by the certified licenced plumber and emailed to backflowprevention.pwc@powerwater.com.au.

Valve test certification report for backflow prevention device PDF, 119.47 KBBackflow prevention, Low Hazard Assessment 20-25mm

Should be completed by the certified licenced plumber and emailed to backflowprevention.pwc@powerwater.com.au.

Backflow prevention Low Hazard Assessment 20-25mm PDF, 75.41 KB